The signature of today’s advanced technology – whether it’s autonomous vehicles, 5G-enabled devices, sensors creating an internet of things, or home routers – is high-speed, high-volume data transfer in increasingly dense packages. It poses new and unprecedented signal interference and heat dissipation challenges for design engineers worldwide.

New products operate at higher frequencies and use more powerful ICs/SOCs to facilitate enhanced data transfer and capabilities. Therefore, these electronics generate an even higher potential for a significant amount of electromagnetic signal interference. But EMI is only one part of the problem. More components make electronics more powerful, but also hotter, thus increasing the need for fast, reliable heat dissipation. Don’t forget about increasing needs for mechanical and environmental durability, space constraints, and lightweight designs. Enclosures are not just simple, aesthetic housing. They are functional, essential parts helping to address EMI and thermal challenges while protecting devices and systems from potentially harsh environments.

Design engineers face a quandary: How do I effectively solve both signal interference and heat dissipation challenges in tight (and shrinking) spaces?

Laird´s innovative Multi-Function Solutions (MFS) portfolio addresses these multifaceted challenges with a unique range of products – from thermally conductive and RF absorbing gap fillers to thermally conductive and electrically conductive gaskets. Combining our decades-long wealth of expertise in EMI products, precision metals, RF absorber and thermal solutions – with the latest material and manufacturing innovations – sparked a new way of thinking and has resulted in a plethora of value-add solutions. Significantly reducing your total cost of ownership and maintaining premium performance while lowering design iteration efforts is Laird´s driver for MFS.

Laird MFS is your one-stop-shop: from simulations/modeling to co-engineering, co-designing and high-quality manufacturing. Challenge us to trust us.

Explore Solutions:

- Specialty Thermal Interface Materials:

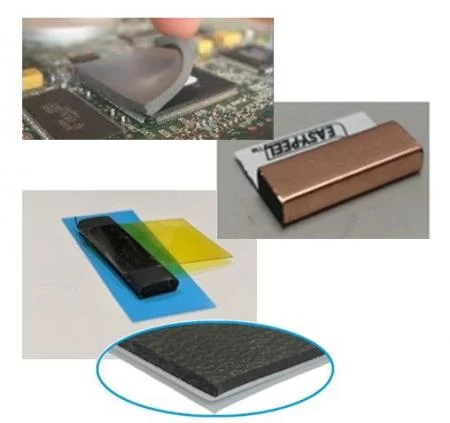

Specialized thermal interface materials with added functionality to solve multiple problems within a single product while saving space, cost, and assembly operations. (e.g. a TIM gap filler that also is a RF absorber).

- Engineered Thermoplastics:

Injection moldable thermoplastics with enhanced EMI shielding, thermal transfer, or RF absorbing capabilities while maintaining the innate mechanical abilities of the base thermoplastic. (e.g. RF absorbing connector housing).

- Emi Shielding & Thermal Interface Materials:

Thermally and electro-magnetically enhanced die-cast, stamped, deep-drawn precision metal parts at board level (e.g. board level shields and TIM/CoolZorb™) or subassembly level (e.g. diecast heatsinks with FIP and TIM/CoolZorb™).

- EMI Shielding & RF Absorbing Assemblies:

- Advanced Sensors:

RF absorbing and electro-magnetically enhanced die-cast, stamped, deep-drawn precision metal parts to reduce high frequency noise or cavity resonance at board level (e.g. board level shields and RF absorber Eccosorb™) or subassembly level (e.g. diecast heatsinks with dispensable RF absorber RobZorb™).

Mechanically unique and enhanced sensors to meet the form factors or assembly needs of advanced electronics (e.g. SMT capable compressible gasket with built in sensor).